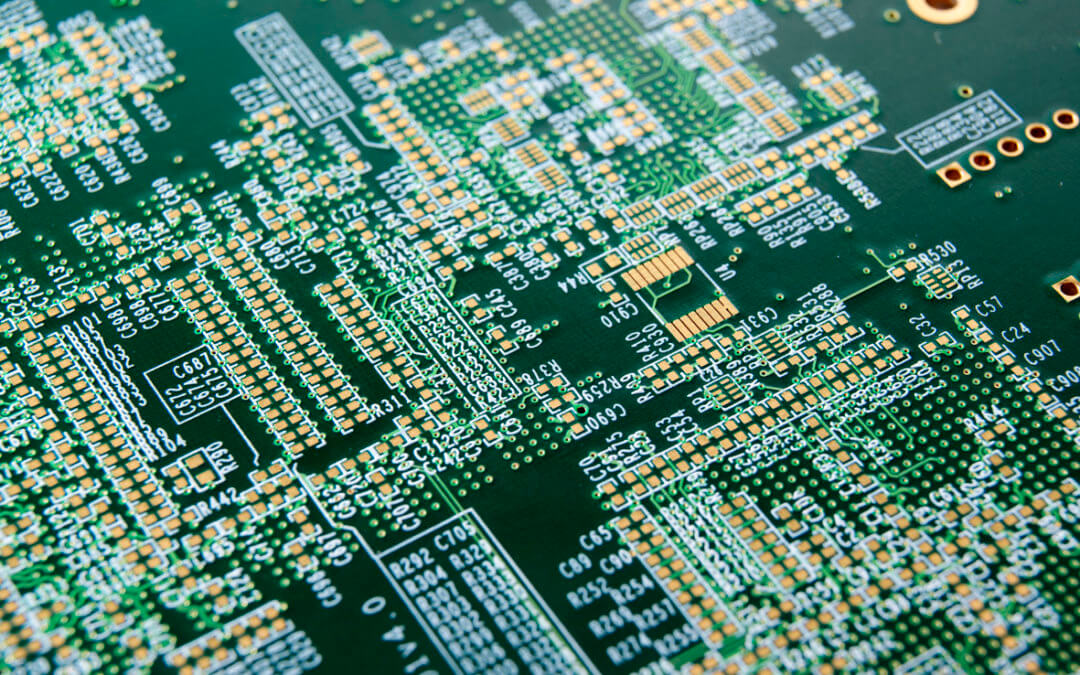

Flexible Printed Circuit Boards (PCBs) offer a highly efficient interconnectivity solution that can bend, form and reform the products they are used in.

It’s as simple as that.

What isn’t so obvious is exactly where and how flexible boards are used: they are increasingly being deployed for an ever-widening range of reasons across an ever-widening range of products.

- Don’t be fooled into thinking that Flexible PCBs (FPCBs) are just used in devices with complex circuitry.

They are not.

Low-tech applications, such as under-the-counter LED lights, often rely on FPCBs because they can make installation so much simpler.

- And don’t imagine they are just used in the wearables market or for products that need to flex in use.

You’d be very wrong.

There are many applications where flexible circuits are required to fit into the device rather than to flex in use. These static applications usually use the less expensive Electro Deposited (ED) copper rather than the more dynamic Rolled Annealed (RA) copper.

Let’s take a look at the growth in FPCBs and consider exactly what they can bring to the assembly line.

The irresistible rise of the FPCB

The global market for FPCBs is expected to be worth a cool $27 billion by 2022.

It is currently growing at a red-hot annual rate of nearly 11% every year.

What’s driving this demand is, undoubtedly, the benefits that FPCBs can offer many different electronic products.

The benefits of FPCBs – and the electronic products that are benefitting from them

· FPCBs enable miniaturisation

FPCBs allow electronic products with strict size constraints to maximise their functionality. Having fewer connectors allows similar functions to occupy less physical space and add less weight to each product.

Flexible circuits are pliable enough to be configured around the edges and folds of devices – and they are durable enough to weather 200,000 bending cycles.

Perfect for:

Miniature devices, such as wearables, sleek fashion accessories, medical devices and smartphones.

Devices where reduced space and minimal weight are critical for performance, such as rockets, cars and satellites.

· FPCBs offer improved assembly quality

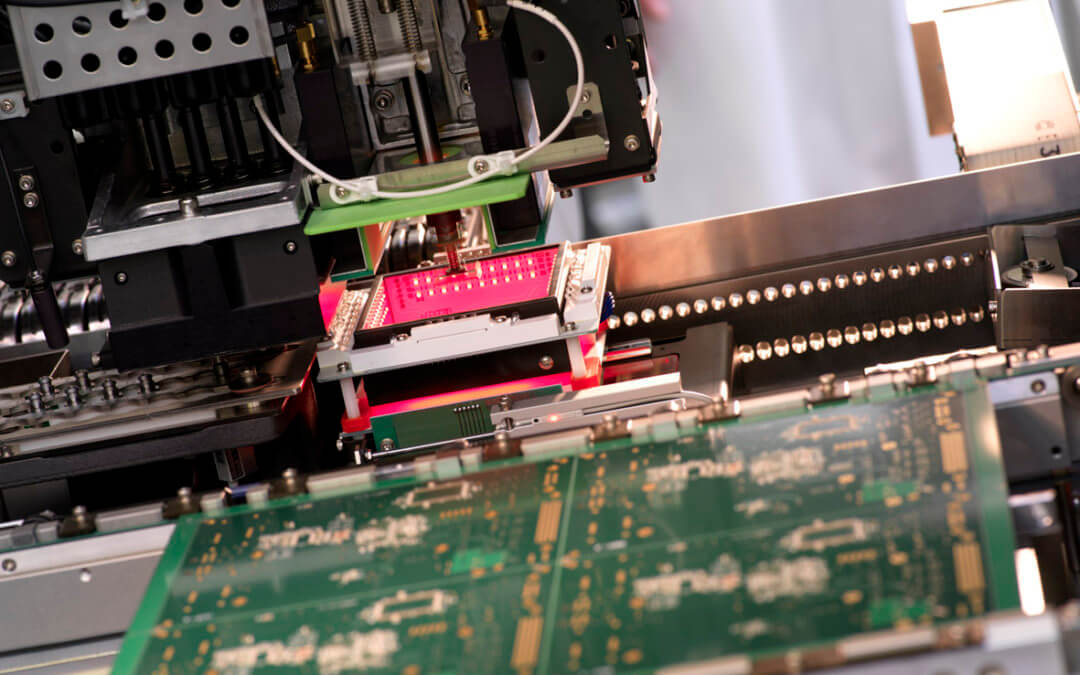

The assembly process for FPCBs is, in many ways, simpler than that of their more rigid relations.

This means that, in devices requiring three axes connections, for example, they can be assembled with minimal wiring, thereby reducing the risk of compromised signal integrity and noise interference.

With fewer parts to solder the risk of connection issues from cold joints is also minimised.

Perfect for:

Cameras.

Motion sensors.

Electronic compasses.

Microelectromechanical systems (MEMS) gyroscopes.

Accelerometers.

· FPCBS provide enhanced board durability

The lighter weight and reduced number of connectors also improves durability.

The elastic, lightweight circuit can easily absorb vibrations with minimal impact on any internal components.

The polyesters and polyamides that comprise FPCBs are also much more suited to withstanding harsher environmental conditions than rigid boards. Their resistance to extreme temperatures, vibration, corrosion, and exposure to moisture makes them ideal for many challenging environments.

In addition, where needed, portions of a FPCB can be strengthened with a stiffening substrate to increase the reliability of these sections.

Perfect for:

Electronic applications designed for the military, aerospace, medical and automotive sectors.

Printers, keyboards and hard disks, thanks to their resistance to vibrations.

· FPCBs can reduce component costs and risks

While it is true that rigid PCBs typically cost less than flexible circuits, there are some distinct cost savings with FPCBs, many of which may be hidden in traditional cost estimations.

The reduced number of cables, connectors, wire harnesses and overall parts required for FPCB assembly can make them more cost-effective in the long run. This is especially the case when you factor in the upstream and downstream benefits, such as the lowered supply chain risk and reduced maintenance requests that fewer parts offer.

Perfect for:

Remote, unattended devices, such as those used in space or by oceanographers and the oil industry.

And FPCBs just get better and better

It used to be said that material handling, during the manufacturing process of flexible circuits, could account for an unacceptable percentage of production scrap and reliability issues.

Flexible materials are certainly much thinner and more fragile than those used in rigid boards. Flexible core materials are usually between one and three millimetres thick, often containing just half an ounce of copper and with a flexible coverlay that is no more than two millimetres thick.

Yet today skilled operators using specialist process equipment can transport these materials safely and with negligible damage.

Similarly, the flexible portion of these circuits once required laborious manual interventions from manufacturing engineers.

The latest modern software puts all this to rest. Skilled engineers can quickly handle complex 3D designs to stack and test flexible parts in layers much earlier in the production process, where alterations and optimisations have much lighter cost and time implications.

Ready to get flexible?

It’s never a case of either/or.

Hybrid rigid and flexible circuits are often used and sometimes one part of a device may rely on FPCBs while another doesn’t.

That’s where our expert EMS team comes in.

Speak to us early in your design process and we can help you determine the benefits of deciding whether to be or not to be, when it comes to flexibility (hey, that rhymes).

Designing a product is never simple. When that product contains complex electronic circuits and components, the design process is even more complicated, needing to take into account the following considerations:

Designing a product is never simple. When that product contains complex electronic circuits and components, the design process is even more complicated, needing to take into account the following considerations: NPI is arguably not a single step on its own, but rather an enabler for the rest of the

NPI is arguably not a single step on its own, but rather an enabler for the rest of the  Every new electronic product needs to be tried and tested before being launched to market. Rapid prototyping is the quickest and most seamless way to reduce the speed to ramp, while maintaining product quality and lowering costs.

Every new electronic product needs to be tried and tested before being launched to market. Rapid prototyping is the quickest and most seamless way to reduce the speed to ramp, while maintaining product quality and lowering costs. Setting up a supply chain that will guarantee on-time delivery, cost savings and sustainability of components is crucial when preparing any product for a smooth route to market.

Setting up a supply chain that will guarantee on-time delivery, cost savings and sustainability of components is crucial when preparing any product for a smooth route to market. The ‘manufacturing’ part of the process only comes when the previous steps have been taken: managing the actual production lines and taking the product through to fulfilment and shipping is (almost) the final piece of the puzzle.

The ‘manufacturing’ part of the process only comes when the previous steps have been taken: managing the actual production lines and taking the product through to fulfilment and shipping is (almost) the final piece of the puzzle. Managing the end of life of a product is an essential part of the wider

Managing the end of life of a product is an essential part of the wider