Product Continuity Management PCM

PCM supports your product from concept through to aftermarket support

Are supply chain problems impacting your business?

- Is the time taken to get your product to market continuously extended?

- Has your product been disrupted by natural disasters in the past?

- Does your company have processes in place to mitigate unforeseen material shortages?

- How frustrating is communication with your current EMS supplier?

- Are your engineers hampered with constant product obsolescence?

- What revenue did you lose because of supply chain disruptions in 2021?

Product Continuity Management - PCM

When you partner with Chemigraphic, you can be sure your product is in capable hands. 50 years of experience and a proven track record in complex supply chain mitigation planning, we’ve developed our PCM system. What is PCM? It’s a business continuity strategy for your products that provide confidence in our ability to get your product to market on time.

PCM supports your product from concept through to aftermarket support.

Our solutions provide access to component pricing, stock availability, predictive lifecycle, compliance, conflict minerals, counterfeit risk, natural disaster impacts and reusability information all in real time.

We partner with your engineers and together we make better decisions that contribute to a resilient supply chain.

We Will Help You Every Step Of The Way

We partner with your engineers and together we make better decisions that contribute to a resilient supply chain.

Catastrophic Events

Unavoidable catastrophic events across the globe can cause supply chain disruptions which are very difficult to mitigate. For example, the Tsunami in Japan March 23rd, 2011, caused 25% of the worlds silicon wafer supply production to shut down, Nihon Dempa Kogyo, the world’s second largest manufacture of crystals, shut down entirely.

Through our commodity and category expertise, our PCM tools allow us to monitor, in real-time, source factories of the commodities your products use, providing you with up-to-the-minute notifications to pivot and implement mitigating solutions ahead of time.

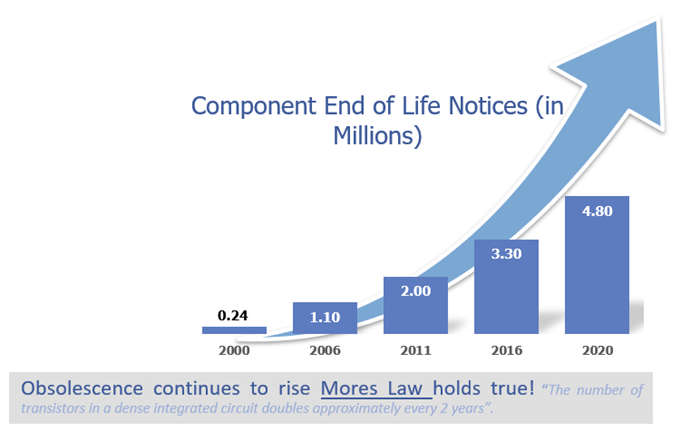

Obsolescence

Each year, millions of individual electronic components are retired or become obsolete. The mismanagement of End of Life (EOL) notices is costing OEM’s millions of dollars annually in design refresh, product delays, and extra inventory sourcing and handling charges.

Using our unique blend of tools and expertise Chemigraphic will consistently provide in-depth health analysis of your BoM with real-time notifications to gain an advantage in providing risk mitigating solutions.

Counterfeit Management

PCM provides a comprehensive, up-to-date reporting and investigation service, and risk mitigation solution. We provide counterfeit, sub-standard, and high-risk component alerts on a daily basis. By combining industry best practices for risk mitigation, vendor qualification, and order screening, the solution allows you to:

- Reduce loss and risk

- Improve decision making

- Identify suspect parts

- Maintain continuous and quality parts flow

Form, Fit and Function Part Replacements

You can reduce risk, increase efficiency, and accelerate innovation by connecting your technical professionals and workflows to our PCM solution. Our unique set of tools grants us access to engineering and technical reference documents from over 400 standards and the world’s most accurate and up-to-date electronic, electro-mechanical and fastener database. This means that Chemigraphic can suggest Form, Fit and Function Part Replacements efficiently, saving you valuable time and resource.

Use PCM To Increase the Security of Supply to Your Customers

- De-Risk through Mitigation and Initiative-taking Reviews.

- Increased speed to market through collaborative engineering.

- Promote customer loyalty by extending the life of your products.

- Reduced Cash impacts from EOL components on your products

- Support to Re-life Products

- Mitigation Against Revenue Loss

PCM Dashboard – Health Check

Considerations:

- Risk of Global Manufacturing Site for Sourced Parts

- EOL Content

- Life expectancy of Parts

- Single Sourced Parts

- Availability of Alternative Parts

- Material Lead-time