How to frontload the manufacturing process for NPIs – and avoid a lot of heavy lifting later

John Johnston, NPI Director, Chemigraphic

Let’s be blunt: DfM (Design for Manufacture) is not something you can bolt-on after the fact.

It simply has to be there from the start. Once a design is released to production, and especially after it has been validated for regulatory compliance, then design change costs can be prohibitive. There is often a singular, and closing, window of DfM opportunity that must be grasped to avoid later complications.

Working closely with an EMS partner from the earliest possible stage ensures that both manufacturing and supply chain considerations are factored into your designs.

And it means they are factored in before there are major cost and time implications.

Frontloading manufacturing concerns is not an additional barrier to faster completion.

In fact, it’s quite the opposite.

Through earlier consideration you cut down on the number of costly design re-starts that may be needed later in the manufacturing process – and you get your end-product to market faster.

By getting a manufacturing supplier involved early on in your design process it allows us to gain a clear understanding of your business objectives and to marry these to the development of your product. This allows you to identify and eliminate potential pitfalls and delays before they arise.

Of course, it’s not all about avoiding problems. It’s also about creating better products.

Through early stage involvement your EMS partner can also ensure optimal efficiency is achieved through practical and often seemingly minor changes. Such adjustments can deliver substantial tangible benefits without affecting your product’s quality or adding cost to it.

Although an individual design amendment may make modest savings if taken in isolation, this benefit is of course enjoyed for every item ever made, over the entire lifetime of that product. This often becomes embedded into normal practice that then percolates into other designs thereafter, making the “accumulation of marginal gains” very significant indeed.

Not all design changes in the electronics industry are caused by issues directly related to the manufacturing process.

Even the most perfectly designed piece of electronics, presenting zero fabrication, regulatory or inspection issues, can create critical delays and costly substitutions if components are not sustainably available.

Unexpected breaks in the supply chain are, in today’s environment, an ever-larger threat.

Product design engineers are often focused on component selection to achieve the desired functional performance and sometimes struggle to see beyond the immediate prototype or small-batch production stages.

A high-capability EMS partner can offer valuable input to help create selections that are also sustainable and cost effective, addressing future requirements when the product ramps into eventual production volumes or off-shore manufacturing locations.

A proactive EMS approach can also widen options to include considerations such as component packaging- selecting functional equivalents that are available in “machine friendly” packaging formats. This then means that automated assembly options can be applied for further cost, efficiency and removal of any risk of human error, considerations which can be overlooked by product design engineers.

The marketplace for components can be fraught with historical supplier mergers and takeovers so an EMS specialist who has oversight of all a marketplace dynamics can often offer advice regarding parts which are exactly the same and built in the same factory, but have different branding and no unnecessary price premiums attached.

However, there should never be any requirement to compromise product integrity by going to dubious or unqualified sources. Any short-term cost benefits can be massively outweighed by eventual corrective measures when things go wrong.

Reviewing the risk of obsolescence is very much a part of designing for the realities of manufacture. These supply chain breaks may be due to:

- Changes in distribution

- Components being placed end of life

- Stocks being allocated as they run low

- Or mergers and acquisitions creating ever-widening ripples.

Regardless of the reason, it’s possible to avoid many problems through early discussions with your chosen EMS partner.

With the benefit of strong supplier relationships, deeper visibility of component availability over a product’s lifecycle can be gained and, with stronger buying power, availability and price stability can be ensured.

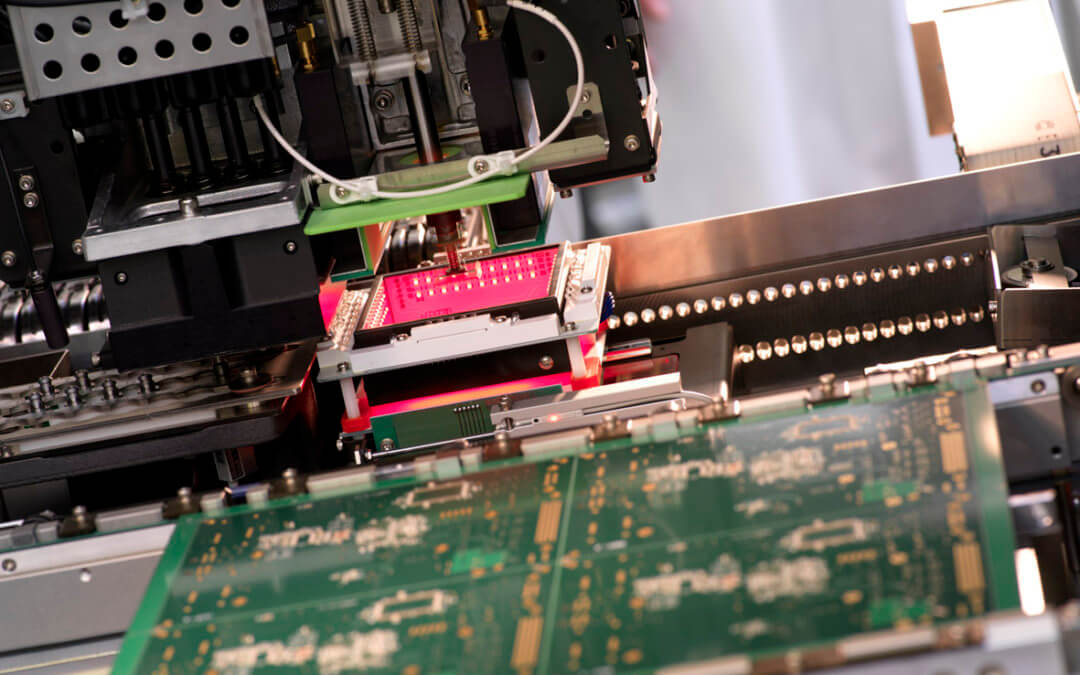

It’s because the frontloading of manufacture and supply chain concerns are so critical to the success and profitability of your designs that we launched our dedicated design centre.

The centre provides an injection of skilled, engineering resources to ensure your designs can be efficiently optimised at the proposal stage.

We offer you the benefit of our 30 multi-disciplined engineers to positively enhance your product development process. There’s a collaborative NPI Ideas Area for you at our Crawley headquarters, where NPIs can be discussed with our manufacturing experts at concept, design and later stages.

We also have an NPI Development Workspace which allows emerging designs to be assembled outside of the normal production environment. This is ideal for processes to be trialled and working models to be constructed, even if it is a start-stop nature. Customer engineering teams are welcome to come along and test alternative options, as they evolve.

All NPI activities are underpinned by our formalised and sophisticated NPI Gate Review Process. This provides flexibility to respond to design fluidity and change, as well as structure and discipline to ensure projects are kept on track and on budget- critical for eventual deliverability.

We’re with you from early engagement in design to creating a design package and getting the NPI ready for manufacture. We’re also available to offer rapid prototyping, testing and lifecycle support.